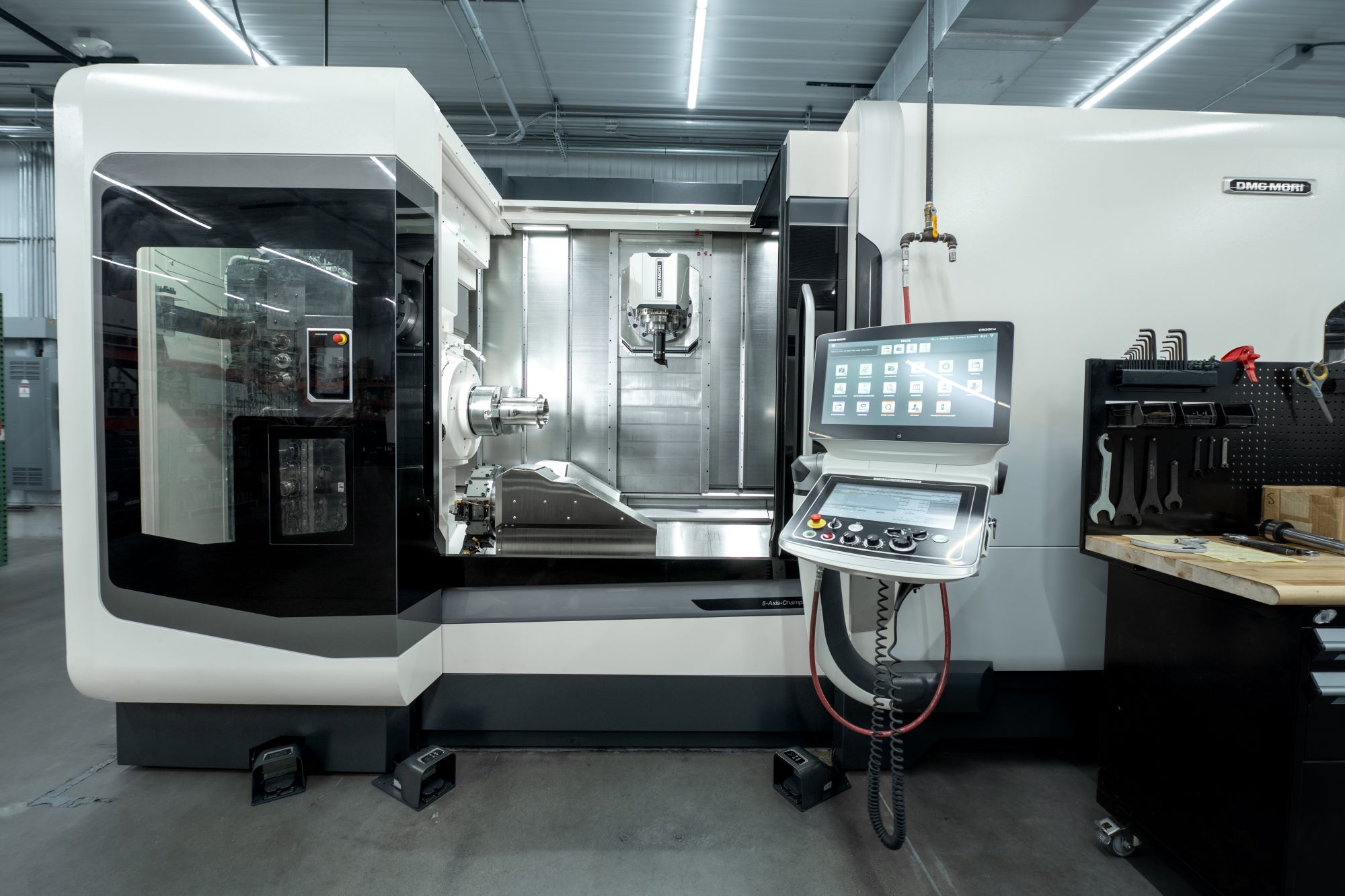

JR Machine is your trusted partner for the efficient production of complex machined parts — and we’re proud to operate on the cutting edge of modern machining. As a dedicated DMG Mori shop, we’re equipped with some of the newest, most precise, and most efficient machining centers on the market today. Most recently, our team finished the installation of two NTX 2500 machines, which enable 5-axis machining with high degrees of precision and speed.

The many benefits that these machines bring to our shop ensure that our customers have short lead times on their parts, tight tolerances on mission-critical components, and the ability to work with even the trickiest materials and designs. Read on to learn more about our new DMG Mori equipment and why our commitment to using the best equipment translates into better service for our customers.

What is DMG Mori?

DMG Mori, a global leader in machine tool and milling equipment, has grown into an industry powerhouse. The company manufactures high-speed precision lathes, horizontal and vertical machining centers, and a wide range of advanced tooling solutions used by manufacturers worldwide.

Unlike other, lower-cost machine tool brands, DMG Mori has a reputation for excellent craftsmanship, extreme precision, and stellar support that ensures machines stay up and running longer. Though choosing to work with only DMG Mori machines is a significant investment, it’s one that pays real dividends to the customers who rely on them for parts.

JR Machine’s Machinery & Capabilities

Our shop features a wide variety of specialized equipment that allows us to craft complex components from tough superalloys like Inconel, Hastelloy, Toughmet, and more. Our arsenal includes:

(2) DMG MORI, NTX 2500

Simultaneous 5-axis machining with Direct Drive Motor (DDM) on the B-axis; through-spindle coolant system and chip conveyor; 26.4 maximum turning diameter; 63.6 maximum turn length

(2) DMG MORI, NLX4000Y

Axial and radial live tooling; tailstock; chip blaster high-pressure coolant; 19.6 maximum turn diameter; 29.3 maximum turn length

(2) DMG MORI, NZX2000

Dual, fully-capable spindles; gantry loader; three separate turret stations with live tooling; a Y-axis; a coolant chiller; high-pressure coolant; 12.6 maximum turn diameter, 31.9 maximum turn length

(8) DMG MORI, NLX2500SY

Sub-spindle lathes with axial and radial live tooling; chip blaster high-pressure coolant; part catch/conveyor; 14.00 maximum turn diameter; 49.00 maximum turn length to 27.7; lns “quick six” 6′ bar feeders

(12) DMG MORI, NLX2500Y

Axial and radial live tooling; tailstock; chip blaster high-pressure coolant; 14.0 maximum turn diameter; 27.7 maximum turn length

(2) DMG MORI, NLX2500Y

Axial and radial live tooling; tailstock; chip blaster high-pressure coolant; 14.0 maximum turn diameter; 49.0 maximum turn length

(1) DMG MORI DURA TURN 2050

W/LNS 4′ bar feeder.

Our Newly Installed 5-Axis Machines

In an effort to provide even more value to our customers, our team recently added two NTX 2500 machines to our lineup. These centers are equipped with the Turn & Mill Spindle compactMASTER, an advanced spindle design that provides a wide machining envelope. This, in turn, maximizes our productivity and efficiency.

With a Direct Drive Motor (DDM) on the B-axis, the NTX 2500 delivers simultaneous 5-axis machining for extreme levels of precision. The addition of a second spindle enables complete 6-face machining, allowing entire components to be produced on a single machine, saving significant amounts of time. To ensure accuracy, the NTX 2500 also features a cooling oil circulation system that minimizes thermal displacement.

Benefits for Customers

DMG Mori machines give our team the capacity to work with expensive and difficult alloys that other machines simply can’t handle. For customers in the space and defense industries, there’s no substitute for using the right materials, and no tech can face those challenges like DMG Mori’s machinery.

Repeatability is another big reason JR Machine chooses DMG Mori. From small-batch runs to high-volume parts contracts, our machines hold their tight tolerances part after part, giving you peace of mind knowing that each of your parts is within spec.

High-quality machines create high-quality parts, and when compromise isn’t an option, there’s no equipment that gets the job done better than DMG Mori. JR Machine is proud to invest in our equipment and provide customers with excellent, dependable service. If you’re looking to learn more about our capabilities, or how we can help you execute your next production run, we’d love to help! Reach out to us today for a quote.